Project example Optimisation

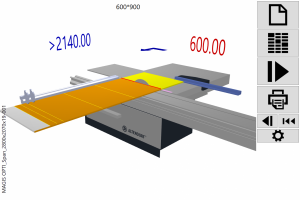

"Digital saw guide + cutting optimization"

A sliding table saw manufacturer wants to complete and upgrade its products with digital, image-based operator guidance that makes complex work processes very easy.

As a result, material and production time are saved. We developed this software from scratch.

Excerpt of the requirements for the software system

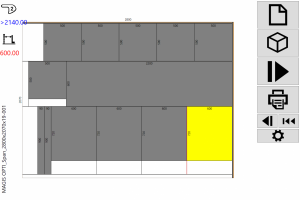

- Cutting processes and cutting sequences are simply shown on the tablet

- Operator is guided visually

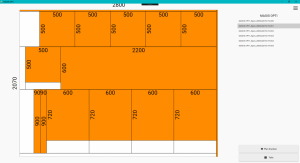

- Data transfer from cutting optimization possible without any problems

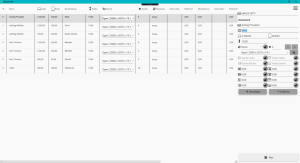

- Label printer

- Dual screen

- Barcode

- Four levels of optimization

- different strategies and materials

- Excel import and export

- Output to "saw guide"

- Label printing