Design as usual, but produce better, safer and faster.

NC-Studio® Windows / Doors

We combine your design software with our 2-component system "CLXMLViewer + NC-Studio®".

The expansion levels

NC-Studio® General

Unfortunately, the NC-Studio® basic system is not sufficient for window and door production.

NC-Studio® Advanced

With other powerful features, e.g. Machining lists, integrated macro editor.

NC-Studio® Professional

For demanding users (control of lasers, integrated barcode scanner operation, integrated debugger, ...)

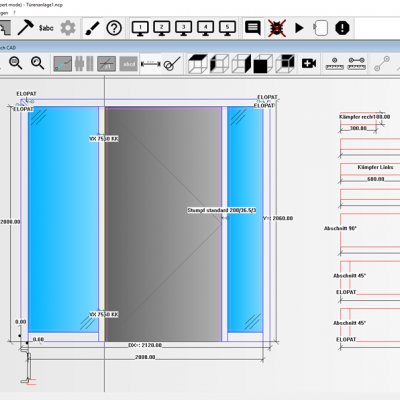

Overview of NCS- Windows/Doors

Your design package combined with our 2-component system: CLXMLViewer + NC-Studio®

CLXMLViewer

All information from your design package is simply transferred to the CLXMLViewer via XML files. It takes care of the control and conversion.

NC-Studio®

The complete CNC programming. You can quickly and easily take care of all everyday window production tasks. Depending on the window software and customer requirements, the interfaces can be designed very individually. NC-Studio® is particularly open to external data. After targeted training, profile systems, drilling patterns and strategies can be created and changed independently by the user.

With version 9 you can now use NC-Studio® as an attractive converter and / or as a programming system.

Tool lists and processing lists have been revised and improved in order to be able to work even easier and more structured (e.g. for window production).

NEW: With the appropriate macro packages, NC-Studio® can now read in and convert various file formats:MPR / MPRX (e.g. from woodWOP)

- IFC format (e.g. from ArCon®)

- CIX (e.g. from bSolid

- XXL (e.g. from Xilog Plus)

- PGM (e.g. from TRIA files)

- PGMX (e.g. from Maestro)

- BTL (e.g. from cadwork)

Overview of NC-Studio® 9

NC-Studio® Standard (for everyone)

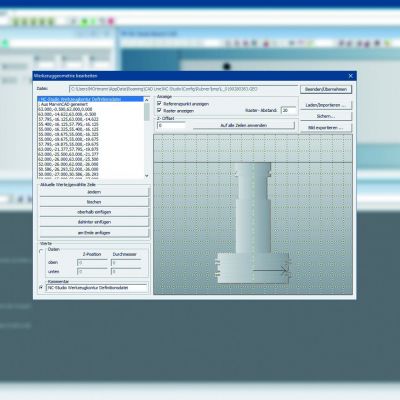

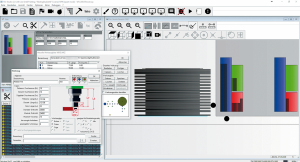

Tool list:

- better presentation

- simplified input

Advanced expansion level

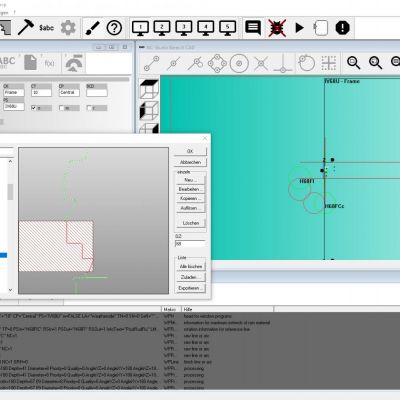

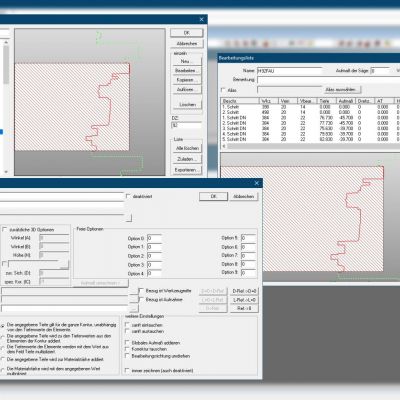

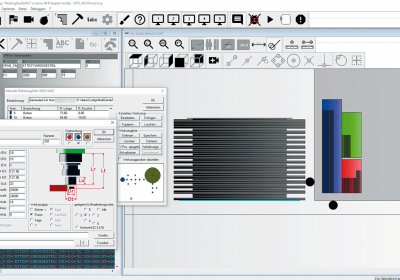

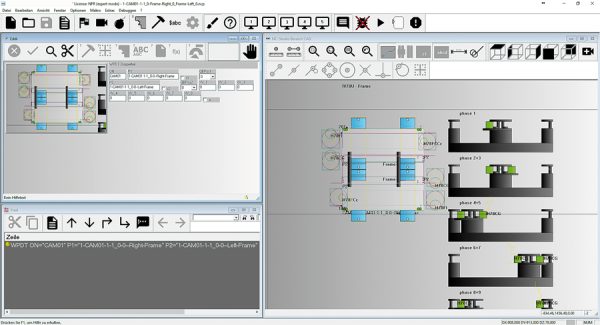

Processing lists:

better presentation / graphics

- better structure

- references

- Alias lists (duplicate)

- Take over tool feeds from tools (e.g. for longitudinal, cross and round machining)

- Sublists (e.g. combine H90_FZ + H90_FA)

- Depth and offset input of tool center and tool holder reference

- Dialogues individually adaptable

- Zoom and move in profile view and profile preview

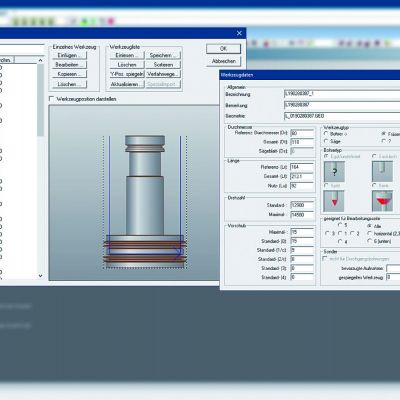

Tool properties dialog:

- Vorschubeingabe für Längs-,Quer-, und Rundbearbeitung

- Werkzeuggeometrie-Dialog verbessert

- neues Layout

Professional expansion level

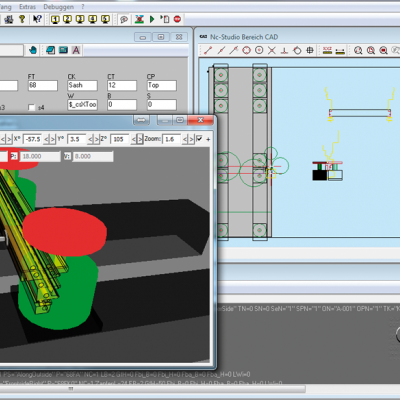

Debugger:

- better presentation

- more possibilities

Flexible CNC programming system

We implement our customers' strategy requests and optimize existing strategies. E.g. 4-sided processing, Rebate the glued sash, full occupancy of the table (linear processing) or optimized pendulum processing.

Special functions especially for the production of wooden windows

- Safety for tools and machines

-

Optimal comfort

Highlights

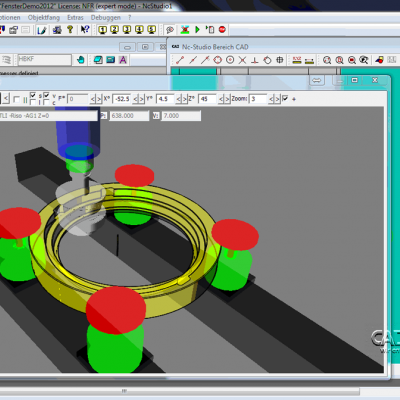

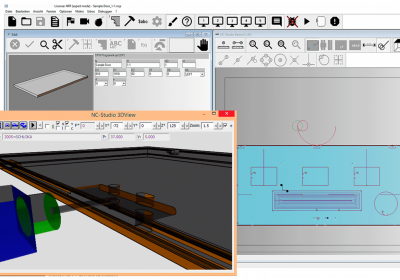

- Presented pragmatically and realistically, you immediately recognize the result of your Programming work.

- Easy parameter specification - direct graphic control. Each step in a processing list has its own parameters. Feeds, references and all other parameters can be easily and quickly specified and immediately checked graphically.

Expansion options

- Integratedprogramming language, integrated debugger, open, expandable postprocessor concept. Rebate changes.

- Strategies to optimize speed and quality can be easily chosen. Rolling in the counter area helps, e.g. to prevent tears.

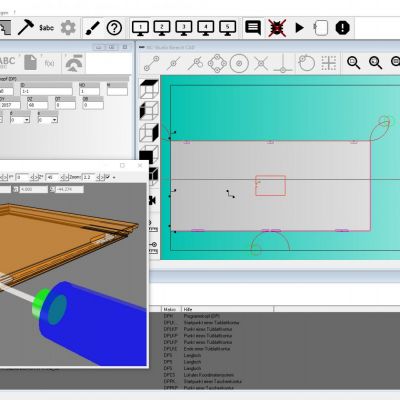

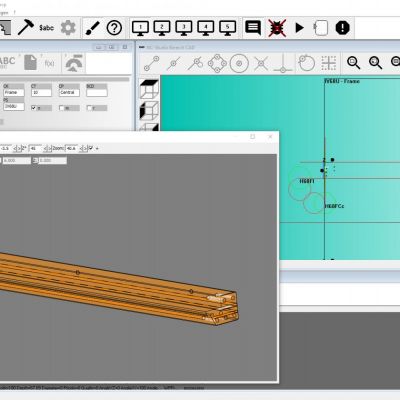

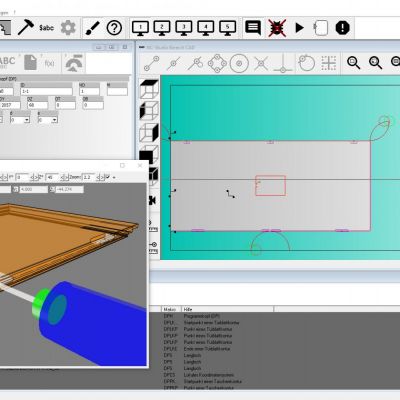

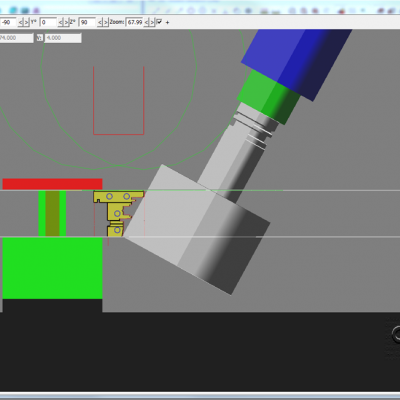

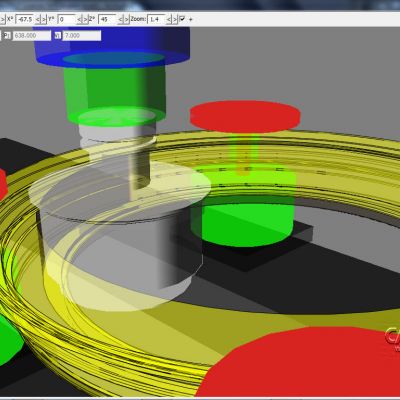

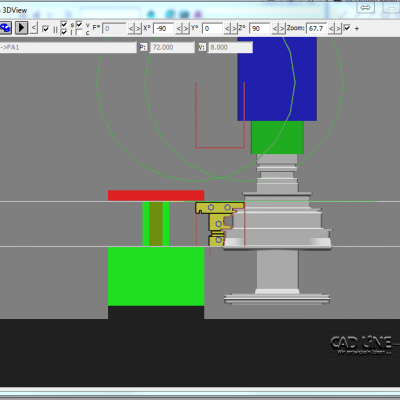

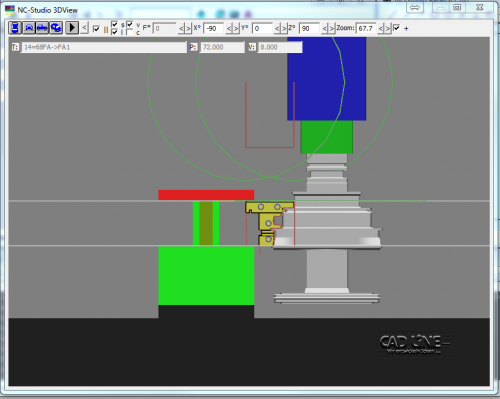

The additional module TV allows the removal of the tools to be displayed in the 3D simulation. The result of all tool movements is displayed. The simulation of the removal is based on the cuboid defining the base plate. Profile tools that are created with a contour are taken into account as well as an inclined plane and drilling tools. The representation of saw cuts may differ from the real produced part due to machine-related conversions. Likewise, displacement of the part during processing by loading devices or the operator is not taken into account.

By specifying points of contact, material or waste can be determined, which NC-Studio TV then takes into account.

Alternatively, the representation of the part can also be selected as a grid. The result of the removal can be exported as an STL file and used for further display in separate programs.

NC-Studio is at least required as an advanced license for the module.

The calculation of the removal can be very computationally intensive, depending on the processing and tool geometries. A suitable processor with a powerful graphics card is strongly recommended.