Project example special solution / connection of a Becker special machine

„Frame production in longitudinal through-feed“

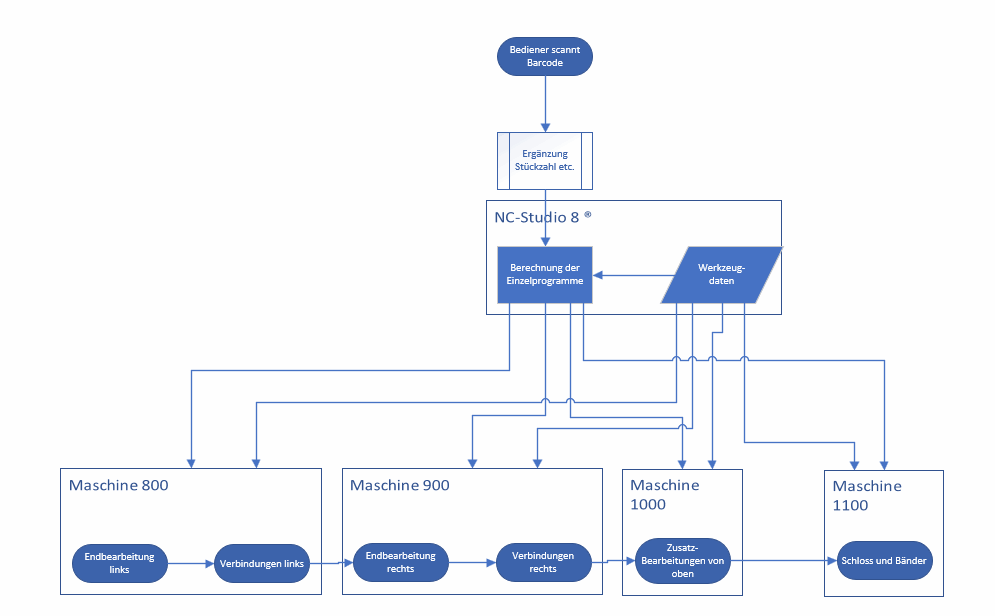

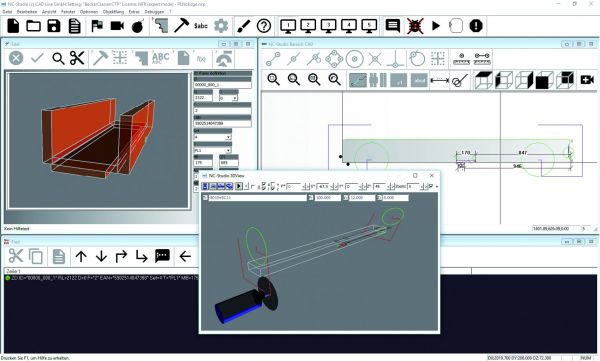

This is about the special control of a system for pressing, processing and packaging special frames. About 20 different frame types must be produced by the system. NC-Studio®8 served as the basic program for the development of this new special programming system.

The special task of this project was to provide programming with which the customer can create, test, maintain and optimize his variety of types himself.

Project description frame system

- The necessary programs for every situation should be generated from the elementary data of the frame type. The wall width, number of hinges, lock and the desired frame parts must be sufficient to define the products

- Ensuring flexibility - The machine has four processing stations with a total of nine CNC channels, which can all work at the same time. Each station requires its own program

- Creation of the required postprocessor on site with immediate tests and adjustments.

- NC-Studio® offers tools for structured programming.

- Optimized cycles for bags, hinges, striking plates are combined individually in macros, making every frame type easy to process.

- Training and active participation of the customer in the commissioning process.

- Running in with the customer on site.

- Ensuring that the customer can look after the system and can independently expand and optimize all processes.

- CAD Line responds promptly to all customer requirements and provides the user with a permanently successful solution.

Process overview frame installation

This is how it works!