Nesting effectively and conveniently.

Nesting-Studio©

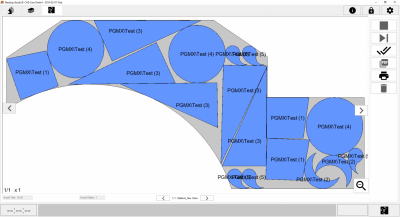

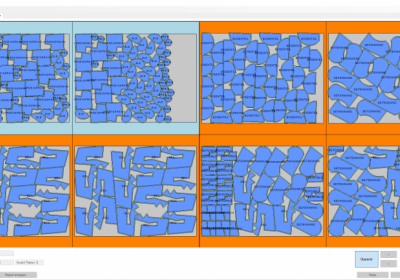

The perfect nesting solution for YOUR individual production. Up to 20% material savings compared to standard solutions.

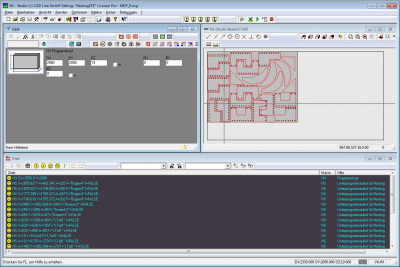

Nesting-Studio© is a combination of the best available nesting algorithm and the convenience of a CAD Line solution. Nesting is always an essential optimization factor in the manufacturing process. For this reason, we have developed Nesting-Studio© specifically for the requirements of our customers. It is particularly customizable and thus contributes greatly to material, time and cost savings in CNC machining.

Areas of application:

Interior construction, rack construction, parts production, stand construction, prefabricated house construction, toy production, etc.

Short description

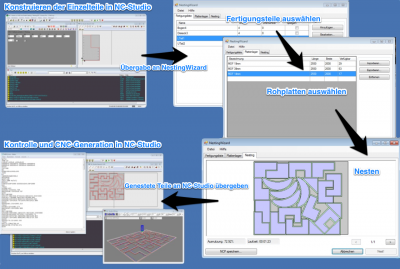

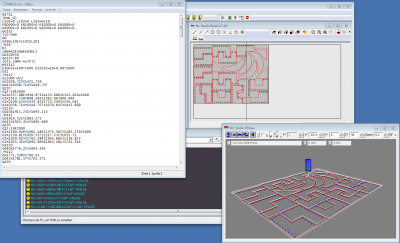

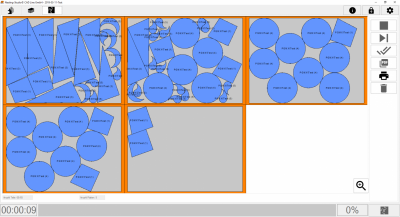

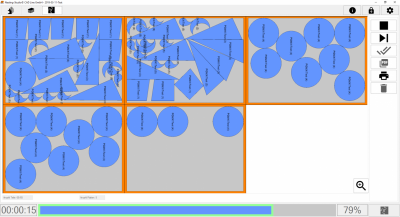

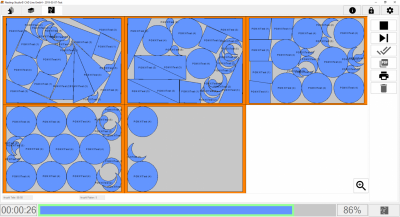

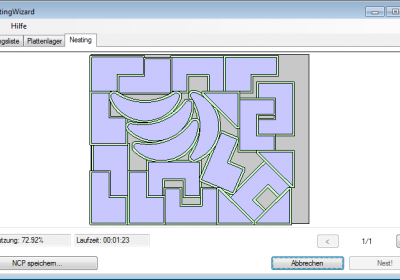

High flexibility in the production of free-form parts

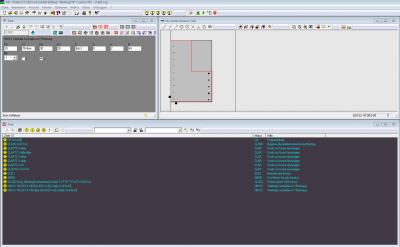

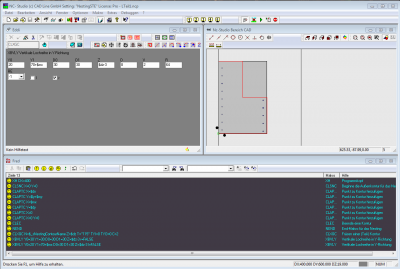

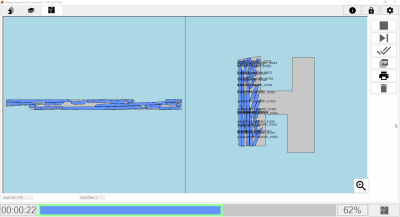

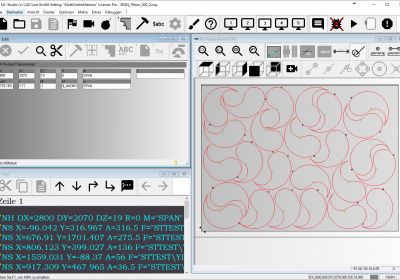

By integrating NC-Studio®, we offer our customers an individually optimized NC program and various optimization strategies. At the same time, both programs are easily adaptable and simple to optimize.

- All processing is possible in one go

- Less handling - less intermediate storage

- Finished free-form parts come directly from the raw plate

- No more cutting is required

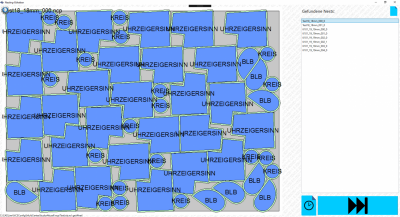

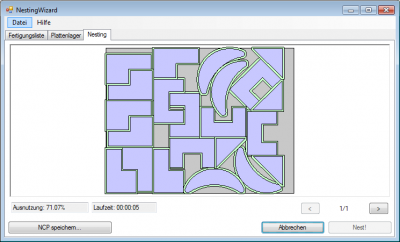

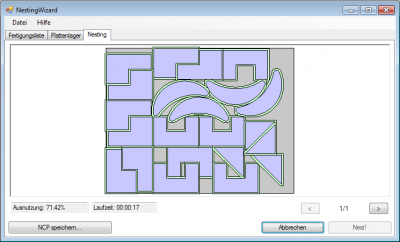

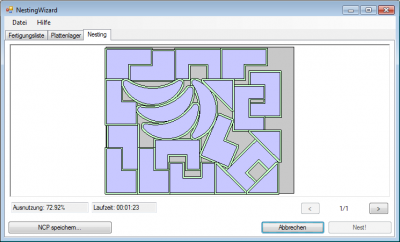

Best nesting core available on the market

Further advantages:

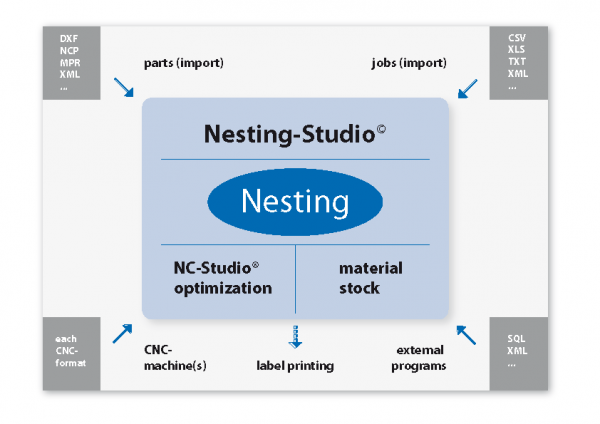

- Seamless integration into existing systems (CSV interfaces)

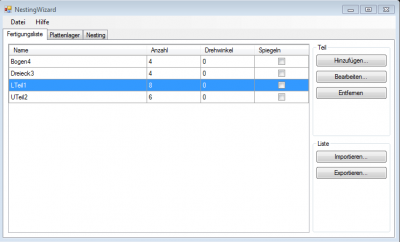

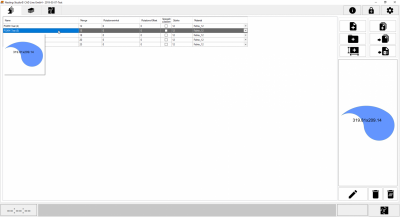

- Simple operation and flexible configuration (setting of nesting parameters)

- Open in all directions (parts and job import, output to machines, label printing, export to various programs SQL, XML ...)

- individually adaptable through special programming

- nesting also with saw cuts• overview of several jobs.

Detailed report on the nesting result in PDF format

Further highlights:

- Automatic contour recognition from milling paths (interference and finished contour)

- Part-in-part nesting for even better utilization of the raw plate

- Multi-stage optimization process for more effective nesting in many application areas

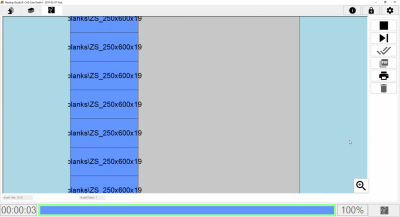

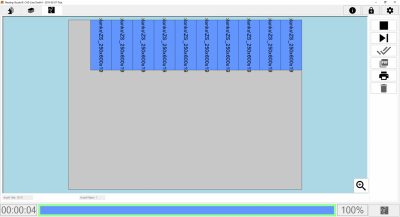

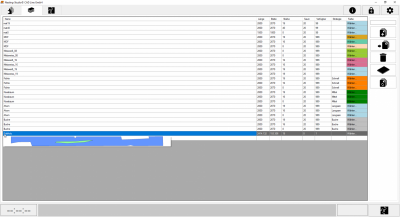

Overview of Nesting Studio

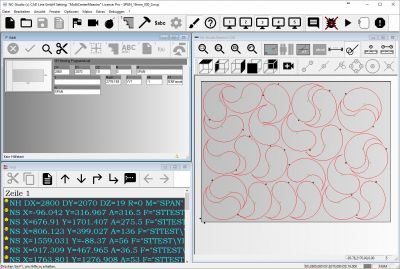

With Nesting-Studio© 3, CAD Line has implemented and realised various customer requests and thus set new standards in the field of nesting.

New in version 3:

- Better strategy integration

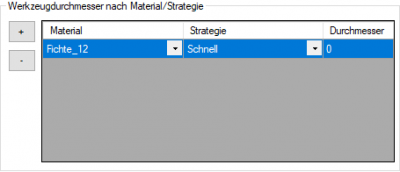

- Milling cutter diameter according to strategy and material

- Add complete program directories

- Filterable material list

- Connection to automated storage systems

- Flexible plate storage import

- Vertical nesting to optimize remnants with grain

- Nesting in irregular outer contours

Up to 20% material savings

Optimal manufacturing process for CNC machining. With Nesting-Studio© 2 we put the quality of the nesting result in the foreground.

Your advantages over "standard nesting programs" (e.g. from the machine manufacturer):

- Best nesting core available on the market

- Up to 20% material savings

- Professional contact for special solutions

- Seamless integration into existing systems (CSV interfaces)

- Special analyzes ( Schreinertraum, special connections, ...)

- Simple operation and flexible configuration (setting the nesting parameters)

- Open in all directions (parts and job import, output to machines, label printing, export to various programs SQL, XML ...)

Highlights:

- Cuts in the nest can also be made with a saw or other units. Nesting-Studio © 2 also processes such parts effectively

- Additional features for the next generation of component nesting

New features of Nesting-Studio© 2:

- Improved presentation

- Comprehensive reporting

- Different versions of label printing

- Improved plate storage

- Milling strategies for different materials

Open in all directions.